- +1 (614) 275-4832

- info@tunnelit.net

- Mon - Fri: 7:00AM - 4:00PM

- We're Hiring. Apply Today!

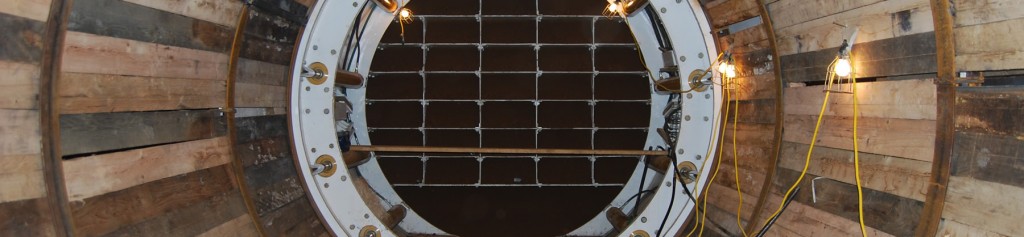

Turn-Key Tunneling prides itself on its experience and knowledge in the arena of hand mine tunneling. Whether it is using a 2-Flange tunnel liner, 4-Flange tunnel liner, or rib-and-lagging with a hydraulic tunnel shield, know that our industry knowledge is the difference maker. Turn-Key’s supervisory staff has over 250 combined years of professional experience in the hand mining tunneling industry. This experience has led to the development and creation of unique hydraulically driven tunnel shields and innovative techniques for various ground conditions.

Tunneling beneath unstable ground with trains passing overhead sounds insane but, we did it…

Why?… Because, we can.

Turn-Key Tunneling incorporated 2-Flange tunnel liner plate and the drift -and- bench method to complete a 15 foot diameter tunnel in Blanchester, Ohio . This entire tunnel was constructed beneath a live railroad track that remained in service, with minimal cover, while the tunneling was performed. The challenge to this tunnel drive was the existence of a split-face condition of part rock and part dirt

Been there. Done that… Take a look at what we have done and what we can do for you.

We tested our best engineered tunnel shields when, Turn-Key Tunneling constructed a 4-Flange Tunnel liner structure utilizing a Hydraulic Tunnel Shield customer designed and built by Tunnel Shields & Equipment to complete a 7 foot diameter tunnel in Louisville, Ky. The entire tunnel was constructed beneath an active highway that remained in service while the tunneling was performed.

What We Do

We Build Kick-Ass Tunnels!

© Copyright Turn-Key Tunneling, Inc. 2025

Created by DiolbyDesign

Site Map

Services

Find Us

Turn-Key Tunneling, Inc.

1247 Stimmel Road

Columbus, OH 43223

Phone (614) 275-4832

Fax (614) 275-4834

info@tunnelit.net

Stay in Touch